How Hard is MIT? by Andi Q. '25

A quantitative analysis

Introduction

Before coming to college, I often wondered how hard MIT was. Conversations with current students led me to believe that MIT’s hardness ranged from “quite” to “extraordinarily”; some even described it as “pretty damn hard”. However, these conversations always lacked the one thing my inner engineer craved most – numbers.

Without objective measurements backing up these results, how could I trust their accuracy, let alone use them in future experiments? Which hardness scale do these results even refer to? And don’t even get me started on the lack of units. I shudder as I think of all the unsuspecting high-school students making important life decisions based on this questionable data. And to think that MIT calls itself an engineering school!

Luckily, all that is about to change. Thanks to MIT’s Department of Materials Science and Engineering (DMSE), I have the perfect tools to conduct a quantitative analysis of MIT’s hardness.

Background

But first, let me address a question that’s undoubtedly burning in your mind right now – what exactly is hardness?

Merriam-Webster defines hardness as “the cohesion of the particles on the surface of a mineral as determined by its capacity to scratch another or be itself scratched” [1]. In simpler terms, harder materials are more difficult to scratch and dent.

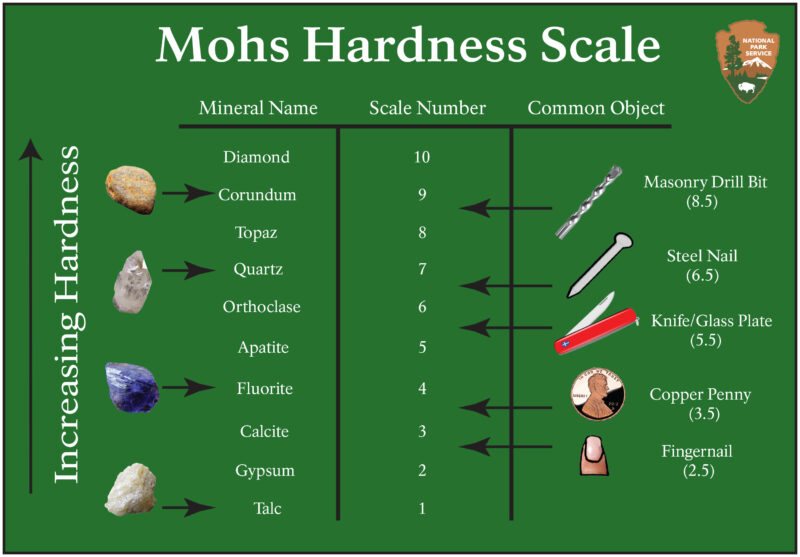

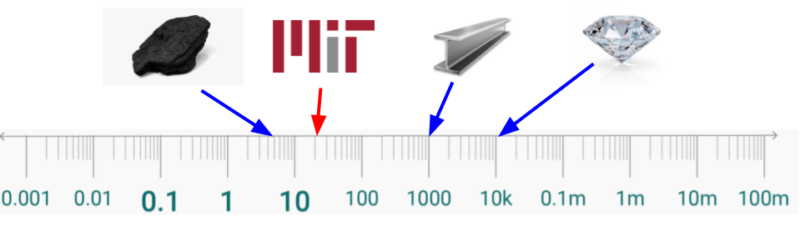

There are several different scales used to quantify hardness. The most well-known is the Mohs hardness scale – an ordinal scale ranging from 1 (talc) to 10 (diamond) where material X ranks above material Y if X can scratch Y [2].

Figure 1 – Mohs hardness scale for some common materials [2].

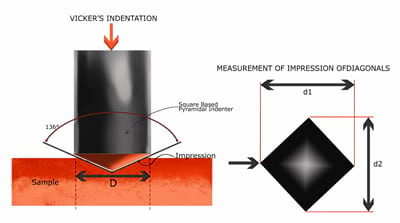

Figure 2 – Schematic of the Vickers hardness test [5].

Materials and Methods

I asked several MIT students about what they believe makes MIT hard. From this survey, I concluded that the chief contributing factor to MIT’s hardness is its notoriously rigorous schoolwork. I further broke down this schoolwork into four subcategories:

- Homework assignments (also known as “psets”).

- Exams.

- Lab assignments and design projects.

- Majors as a whole.

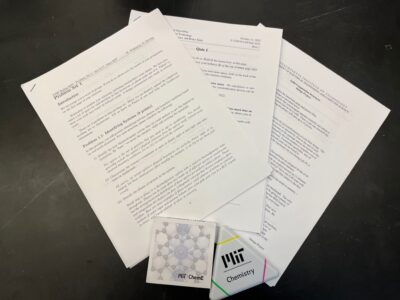

Based on these four subcategories, I collected five different samples to test:

- My 3.020 (thermodynamics of materials) psets from this semester.

- My 6.1220 (design and analysis of algorithms) midterm exam from last semester.

- The 6.1910 (computation structures) design project from spring 2009.

- A stack of sticky notes I received from the Department of Chemical Engineering.

- A plastic highlighter I received from the Department of Chemistry.

Figure 3 – The samples I used, arranged left to right.

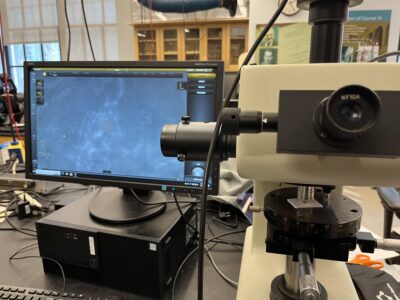

To test these samples, I used a Vickers indenter (generously provided by the DMSE in their all-new “Breakerspace” opening in July) to measure their Vickers hardnesses. To correct for human error, I took three measurements for each sample using the indenter and used the average as my final reported measurement.

Figure 4 – The Vickers indenter with a sample loaded.

I then used ad-hoc tests such as Mohs hardness tests to confirm my results.

Results and Discussion

First, I tested my 3.020 psets. Thermodynamics is one of the most challenging classes I’ve taken so far at MIT because of how unintuitive the concepts are, and the homework certainly reflects that… but exactly how hard are the psets?

Immediately after I loaded the sample into the Vickers indenter and pressed “measure” to find out, I encountered my first problem – no indentation was visible, even after repeated measurements! This result meant one of two possibilities:

- The sample was harder than a diamond…

- Or it was so soft that all indentations sprang back (like a flat marshmallow).

Figure 6 – No visible indentation.

I then bent the psets without them shattering, meaning they were ductile. This result suggests that the second possibility is the most likely. For now, though, I left my lab notebook blank.

Next, I tested my 6.1220 midterm exam. The median score for this exam was 61 out of 120 – by all measures, the most difficult exam I’ve taken so far at MIT… but all that is irrelevant when measuring material hardness. Once again, however, the results from the indenter were inconclusive.

At this point, I was rather desperate to get some numerical data, so I attributed these disappointing results to the fact that 6.1220 dealt with software. Surely, I asked myself, the 6.1910 design project – a project centred around designing efficient hardware – would yield better results?

Unsurprisingly, the design project (along with the chemical engineering sticky notes) sprang back like marshmallows.

Could this be why there have been no previous quantitative studies on MIT’s hardness? Is the measurement process simply too complex for a silly little undergraduate like me to perform? I considered giving up here, but I still had one remaining sample to measure, so I pressed onward.

As I pressed “measure”, I held my breath and crossed my fingers. As the microscope slowly focused on the sample, the impossible happened – a faint impression of a square appeared on the computer screen. I could finally extract a numerical measurement!

Figure 7 – A visible indentation at last.

I then made two more measurements and extracted a hardness value of 194 HV for the highlighter. This value is roughly the hardness of polypropylene [4] (which makes sense if you think about it).

In my excitement, I gripped hard on the stack of previous samples I was holding. To my surprise and delight, my fingernails scratched them, which reminded me of another tool I had at my disposal – the Mohs hardness scale!

Knowing this, I grabbed a nearby pencil and piece of chalk and measured 1.5 on the Mohs hardness scale for all four samples. These values correspond to roughly 20 HV – an order of magnitude off from the highlighter’s hardness value, though that data point might be an outlier.

Conclusion

MIT, with a median Vickers hardness value of about 20 HV, is about as hard as paper. In other words, not very hard at all.

Figure 8 – MIT vs. other materials on the Vickers hardness scale. Note that this is plotted on a log scale.

All numbers presented in this blog post are rough estimates, so take them with a grain of salt. Nevertheless, this post is a big step in the right direction, and the findings presented here will open the door for future studies about the hardnesses of different colleges.

Acknowledgements

I’d like to thank Dr Meri Treska for letting me use the DMSE Breakerspace’s equipment. I’d also like to thank you, the reader, for making it this far in this blog post.

References

[1] Merriam-Webster. Hardness. https://www.merriam-webster.com/dictionary/hardness. March 2023.

[2] National Park Service. Mohs Hardness Scale. https://www.nps.gov/articles/mohs-hardness-scale.htm. January 2023.

[3] Encyclopedia Britannica. Vickers hardness. https://www.britannica.com/science/Vickers-hardness. December 2018.

[4] Marlin Steel. Polypropylene material properties. https://www.marlinwire.com/blog/7-need-to-know-polypropylene-material-properties. January 2020.

[5] NextGen Material Testing. Understanding the Basics of the Vickers Hardness Test. https://www.nextgentest.com/blog/understanding-the-basics-of-the-vickers-hardness. September 2019.