Do you live in Zambia? Malawi? Ghana? by Kim D. '09

If you could send me some African dirt, that would be amazing! (And illegal. But still amazing.)

On the most excellent advice of my blog-readers, I have added D-Lab to my schedule. This involved dropping a few other activities of minor importance (biking for fun, blogging, sleep) but hey, saving the world involves sacrifice, right?

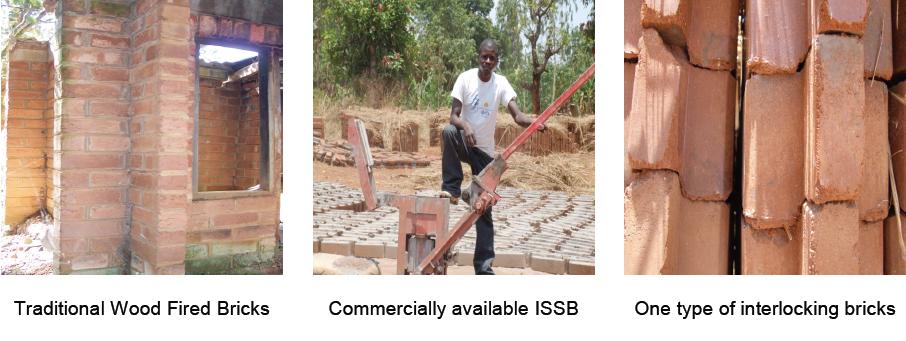

I’m working on designing something that makes Interlocking Stabilized Soil Bricks. Basically, it’s a machine that applies some sort of pressure to some mixture of dirt and concrete. It has to be able to make a strong brick using pressure instead of heat. Also, the bricks should have a shape that lets them interlock, so that they don’t need mortar to hold together.

And of course the machine should be fast and cheap and easy to use and produce strong, perfect bricks.

My group is throwing around all sorts of ideas to apply pressure right now; screws, levers, pulleys, impacts, vibration, the soul-crushing weight of all the work at MIT … But what we could use are facts.

Do you know how Zambian/Malawian/Ghanaian dirt compares to dirt commonly found in, say… Massachusetts? Or what sort of building materials are just laying around in these countries? What sort of skills people have? Have you used one of the existing machines, like in the picture? How was it? What sort of buildings do local people usually build (round? square? tall?)?

Did you play with mud as a child? I’ll take any leads…

^ seconded!

Sorry! Is that better?

May I suggest using wet sediment/dirt and using the evaporative effects to create a structural unit. You might want to ask a materials or chemical engineer for this kind of advice, which is one of the options that I will be taking at MIT.

Just make sure that if you don’t use a kiln or some other sort of firing technique that you mix in grasses or something similar. Even though African nations do not get a /lot/ of rain, the rain they do get is often torrential (specifically Zambia) and that can ruin pure mud bricks.

May I also suggest checking out Lincoln logs? That sort of interlocking pieces were used for /ages/ on the western frontier with logs, so why can’t something similar be built with bricks?

And about the soil – from the looks of things, Ghana has a lot of rainforest soil, but the only things I could dig up about Zambia and Malawi is that they are bordered by water (a river and lake Nyasa, respectively)

Hope it helped.

@kimd

yep, thanks.

sorry, i’m not very knowledgeable about masonry or crust geology… so i’m afraid I don’t have anything useful to contribute here.

I agree that you want to start with wet dirt for better cohesion, but I think the idea was to avoid heat altogether if possible. At least a little baking may be unavoidable, but the sun could do that in the time it takes for the concrete to cure. Have any sort of experiments been done?

As for the mechanical aspect, what about a locking crank that could hold the pressure?

Hey!!

I’ve played with African mud before!! (and eaten it….I was a baby) lol

ok..yea, I was born in Ghana.

And I also went to boarding school there for sometime during my academic career (sayy 7th,8th, and 9th grades)

ANDD there happened to be a lot of construction going on on campus during my time there.

Sadly, I certainly cannot provide soil, being that I’m in NYC I haven’t seen the bare ground for some time now.

If you have any questions, feel free to email me at [email protected]

or AIM @ Torfeek

I am currently on Facebook fast for Lent, so I cannot be reached there. (3 weeks and still strong!!!)

I’ll answer your questions to the best of my memory.

And GOOD LUCK TO US ALL in RA!!!!!

World Soil Information

You can probably make an imitation of the soil here by obtaining the components and mixing them… although the organic matter might be different. Just a guess?

dirt? wouldn’t the word you’re looking for be soil?

dirt? wouldn’t the word you’re looking for be soil?

Are there any soil scientists at MIT? If not, you might consider reaching out to someone in the soil science department at a nearby ag school (UMass, maybe?). Believe or not, some people spend their entire careers studying soils.

YES!

One of my favorite childhood activities: putting on a swimsuit, going outside, turning on the hose, and painting myself with mud.

…which inevitably led to being sprayed with ice-cold water before my mom allowed me back in the house. She didn’t share my opinion that mud makes a fantastic decorating material. The neighbors certainly got their share of entertainment, as did the repairman who happened to be up on the telephone pole one day when my brother had to strip down and get hosed off to come inside.

Oh, mud. =)

So importing soil without a permit is illegal? Does that mean that if I forget to wash my clothes before coming home I’m a smuggler?

I was in Tanzania doing volunteer work over summer (building schools) and we made bricks using concrete that we made out sand, water and cement. Once we mixed everything together, we would fill a brick making machine, which would have a wooden board at the bottom of it, with the mixture and slam the lid down to get the mixture compressed. Then we would push up the wooden board (so that we wouldn’t ruin the brick by directly touching it), carry the brick away and leave it in the sun to harden.

Although this might not work in all the countries you mentioned, since they have wetter climates.

Actually, if it’s going to sit in the sun all day, why not incorporate some from of solar oven? All you really need is some nice conductive metal and a shiny eliptical dish…could be put around the press after the manual work is done…though if you could harness the soul-crushing workload, more power to you (maybe use old paper as fuel? shipping would be costly, though).

that could work, but it could just be extra expense, since something else can be done while bricks are drying. the most useful improvements would be a way of mixing cement with sand and water (I had to use shovels, which is tough work)and a way of operating the machine more quickly, perhaps by making several bricks at once, although this would probably need a lot of force

When I was in Africa, the dirt was, as someone mentioned earlier, on the sandy side.

Building materials, if I recall correctly, were very much on the basic side of things, so don’t factor in anything too complex being readily available.

Generally people I met were pretty skilled and could turn their hand at most things. At the same time there’s a lot that needs to be done in any one village at any one time, so something simple which doesn’t require a great deal of time to train people to use would definitely be an advantage.

Buildings in general tended to be square or rectangular; the shapes are easier to manage than circular buildings, though no doubt the corners could be shaped in a more circular fashion if it made it easier to interlock bricks that way rather than meeting them at right angles.

I hope that helps.=] My memory is a little rusty, I haven’t been to Africa since late 2007, but that’s what I can remember about the buildings and so forth.

Hehe~ despite knowing nothing about African mud, i used to grow up on a chinese farm & taste mud & build castles out of wet mud~

World soil info z helpful, or maybe u can develop a research topic on ur own at mit & lead it to a month in Africa?

Kim, are you sure you can replace the baking process by just applying pressure?? when the bricks are heated/baked[here I’m not referring to sun-drying process that removes moisture], there seems to be a physical/chemical change; so even when there is a torrential rain, the bricks don’t mix up with water. However you may look into the baking process involved in those countries, and try to make it more effective & energy efficient[‘cos I have seen the brick firing process in my country, they stack up the bricks in a huge arrangement, line it with coal inside. After sealing the whole structure the coal inside is fired, this burns for a week. There was a lot of brick wastage involved due to improper heat distribution. And also I don’t think it was fuel efficient!]

hey, wait a second, I skipped the word ‘concrete’ while reading your blog. The countries you mentioned and many others use pure soil bricks, the explanation I gave above also involves pure soil bricks! ….I’m sorry for that!!

concrete, I mean cement.

well its africa..and even the dryest areas have mud/clay in some parts which is cheap and used for building…the machines are very basic..they make rectangular bricks(that i’ve seen)which come out pretty wet and have to dry in the sun..so i’d say neither the temperature nor the pressure is significantly high..you may be confusing their machines with the modern ones. as for the shapes of the buildings, you have a lot of round huts and rectangular fences..

Kind of an obvious point – from what I understand, you want the machine to work independently of temperature, but it would be difficult to prevent Zambia’s scorching sun from affecting the temperature of a machine on the ground during the day. That is, unless you expect the machine to be used at night (which has some merit, but should be specified) or in indoor locations, a relatively simple machine’s function would likely be influenced by light and temperature fluctuations. It might be a nice idea to create an exterior for the machine that can absorb light and channel the energy toward function – kind of a solar wind mill that makes bricks. Just a thought…

from my experience in mw, the dirt is mainly from an anthill which is considered more durable. The tool used is a wooden rectangle that you press the mixture of mad and water in.

You haven’t given your address. To whom do I mail?

Torfficka, thanks for the offer, I will probably contact you to ask some questions in a bit (I have a bunch of unrelated work to finish first).

Shoshie, that’s a good point. We should account for what happens when we don’t provide any heat but there is a lot anyways.

If anyone does want to mail me dirt, you can send it to,

Kim Dietz #334

Random Hall

Cambridge, MA 02139.

Thanks!

I’ve heard of that in the last few centuries people used mixture of dirt and EGG WHITE as bricks in their buildings ((according to the mythes the dirt would be as tough as a cement)).but i don’t know if the same is used in africa or not…..

I played with mud as a kid

Oh, and I’m taking a first! ^^

Neat project, but unfortunately I don’t know much about African dirt. All I can say is that the soil in the northern countries is probably pretty sandy, you know, what with the desert and all.

Captain Obvious AWAYYYYYYY!!!!!!

@Kim ’09

the botched link formatting in the header description is throwing off the formatting for the whole site. at least for me it is.

just letting you know.

No Problem Kim

Good luck with that unrelated work [lol]

–

1 day left!!!

o_o

0_0

0_No Problem Kim

Good luck with that unrelated work [lol]

–

1 day left!!!

o_o

0_0

0_<

O.O

^_^

m/d[^_^]bm/

….stages before and after admissions letter is received….

Gud luck!! to us all

Hmmm…the solar oven shouldn’t be expensive (at the least expensive, all you need is a long roll of aluminum and a basic knowledge of eliptical dishes…heck, if you had some white powder, you could build a dirt relfector around it at minimal costs at the loss of heat). Depending on the size of the bricks, it would be possible to press more than one at a time. Maybe a giant central press to make 25 bricks at a time (5×5, or more, maybe) with four people operating some kind of press on each side (kinda like the reverse of a car jack)…how big are these bricks going to be?

Soil can easily vary from one location (village) to another. Maybe it would be helpful to have information about the major types of soil in those nations. Can you call the embassies? They would be happy to help, I hope.

I am from Nigeria and I guess I can help with the sand thing.

Don’t even attempt to use the soil of America as a medium cos presently I am in Florida and I believe they have the closest thing to the kind of sand in Africa but even then, the sands are miles apart in terms of the basic characteristics of sand. Colour, texture, pH and all that.

In Nigeria, which I know for sure you will have a very good market for your product, there are lots of sandy loam soils, loamy soil and sandy soils in the extreme northern parts especially. The first two soils mentioned adhere a lot to the general properties of their names in terms of mineral matter, colour texture and all that. However if what you need is the sandy soil, there are regions that have soils like that in large proportion but theproblem is in the fact that transportation has to be incured to transport them to where they are needed. If therefore you want to produce machines that will help in terms of making interlocking blocks and all that, it will be advisable you make a machine that will produce bricks from the available loamy soil or sandy loam soils so the huge cost of bricks will be reduced largely as a lot of cost will be cut from the drop in transportation. Outsides the transportation cost, you might want to look at substitutes for cement and gravel.

God Bless!!!

one word for you-Terracotta

we’re using laterite (concrete made from local dirt), it seems to be a pretty popular/easy to get/cheap material

I have lived and worked in Ghana doing IT and Construction projects (non-profit) for around 1.5 years in the last 3.

Now this type of project you are discussing will most likely be used in villages in the southern half of the country where population density is largest and in villages where there is likely not electricity (as they have fairly extensive infrastructure already if they do have electricity).

In this southern half of Ghana where I did my own project there are significant amounts of sand due to the “hammatime” or dry season where the saharan desert gets blown around the world, and the dirt has a very reddish colour, and I believe clay-like makeup.

From what I remember of building an extension to my school there (I was sort of the Project Manager for that) the sand we used to mix with our chippings and concrete had to be shipped from certain areas of Ghana directly, as it was wholly unsuitable for building due to the clay content I believe.

Now I can probably get you more detailed information if you would like as I have “family” and one of my former bosses (German Civil Engineer I worked for in the middle east) there who have built major construction projects there and around the world.

Give me an email if you need more information, perhaps discussing this and your own project constraints can lead me to finding the correct information for you.

I returned from a trip 4 months ago there to finish building a concrete school extension & computer lab, and also we were researching some sites for possible waste-to-energy plants or data centers. This trip involved driving alone many highways in the southern half of Ghana, following the fiber infrastructure (which is quite impressive), and many, many photos being taken around sites.

Sincerely,

Evan Taylor

[email protected]