Not in Kansas Anymore by Allan K. '17

oh, wait...we actually are. Day 1 with the MIT Design/Build/Fly team.

We’re in a hotel room and we’re watching Men In Black (preceded by Aviator and Family Guy) while assembling our airplane to drown out the raucous men out in the parking lot blasting loud country music.

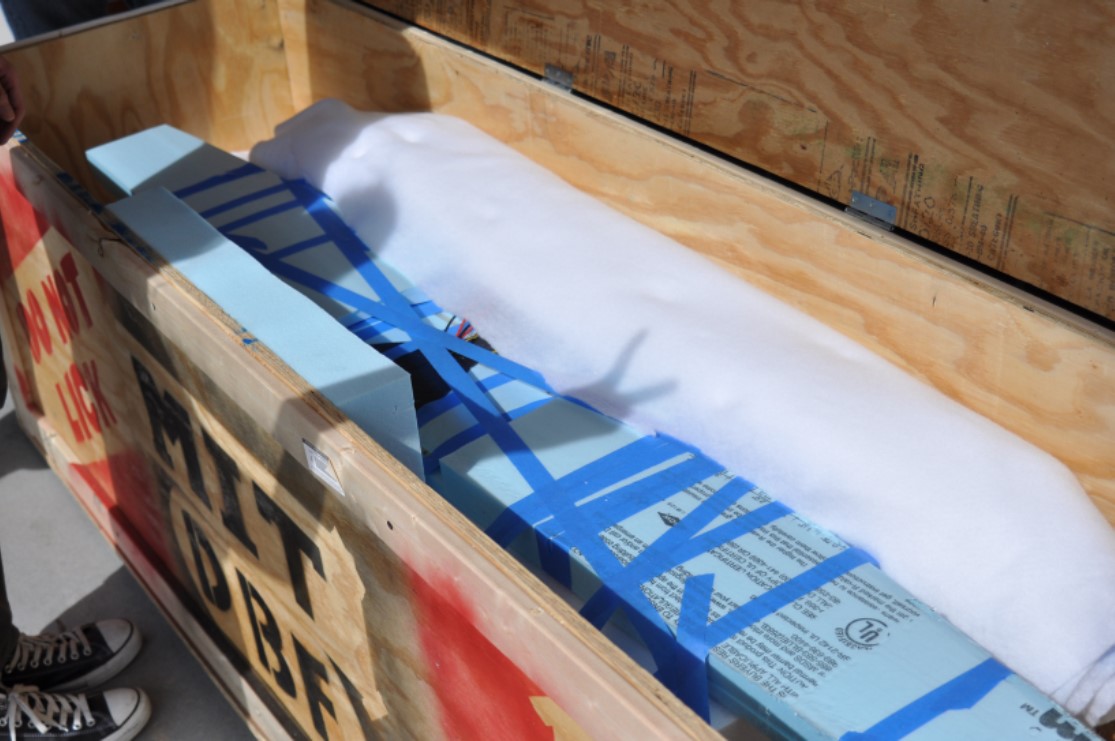

While all you sprightly prefrosh came rushing into MIT for the one and only Campus Preview Weekend, the MIT Design/Build/Fly (DBF) team was in lab, packing up and headed out to Wichita, Kansas for the 18th Annual AIAA DBF competition. Our plane, having been shipped last week in a big wooden crate carefully lined with soft things and packing foam, was waiting for us.

(You’d be surprised how many people want to lick our airplane. It’s pretty sexy.)

What, you might ask, is DBF?

DBF is exactly what its name sounds like–a team of students designs, builds, and flies a remote-control aircraft to fulfill a number of mission requirements, and do it better and faster than all the other teams. It’s about as hands-on as aerospace engineering gets, from the initial design brainstorming to the hours of mixing epoxy and building composites out of kevlar, carbon fiber, and insulation foam. This year, the design theme is “backcountry rough field bush plane.” The plane simulates a medical plane for carrying cargo (1-pound 6-inch cubes) as well as a combination of four blocks simulating medical attendants standing next to patients on gurneys. The plane also has to be able to taxi for 40 feet on corrugated roofing. The theme is different every year–two years ago, the mission requirement was to carry 2 liters of water to a 100-meter altitude and then dump it out of the airplane like an aerial firefighter.

The MIT DBF team works out of the Gelb Lab in the basement of Building 33 (take a tour if you’re on campus!). It’s decked out with all your standard machining machines (mills, lathes, a waterjet), as well as two wire cutters for cutting insulation foam and one CNC foam cutter for more finicky foamcutting. DBF has a closet full of rolls of kevlar, carbon fiber of all different weaves and weights, bottles of epoxy and rolls of adhesives, plus all sorts of other knicknacks, tools, and materials needed to build and fly airplanes. Molds for our fuselage, wings, and tails. Vacuum pumps for composite layups. Motors and propellers and electronics galore.

If the MIT DBF team goes to Kansas, though, we take our lab with us. As of 6:00 AM this morning, the Gelb Lab has gone mobile. We’ve packed pretty much all our tools (sanding bars, drills, dremels, soldering irons, razor blades, etc) into our check-in luggage and our carry-ons, as well as enough backup parts and materials to rebuild our airplane three times over in case it spontaneously combusts or lawn-darts into the ground. Here we are waiting for the subway:

The TSA probably had a lot of fun going through our bags of chemicals, batteries, and cutting implements.

When we arrived in Kansas a subway ride, two airplanes, and a layover in Chicago later, I realized that I’d forgotten it was possible for the weather to be over 50 degrees. It’s a simmering 70 degrees here–t-shirts and shorts and even sunscreen–and no signs of changing much over the weekend, either. It’s hot, hot, hot.

We loaded up our suitcases into rental cars and drove over to our hotel, a sunny Days Inn by the highway, where we picked up our finished airplane and lovingly uncrated it from its wooden womb.

We then promptly unpacked our laboratory from our suitcases and set up shop. We had an airplane to assemble. The bathroom turned into a dremeling station (and soon became appropriately covered in blue foam dust), while the beds were repurposed as lab tables.

We’ll be up early tomorrow morning to flight-test our baby once its fully assembled.

Stay tuned–because I’ll be liveblogging on our progress every day this weekend to keep y’all posted about how awesome our airplane is. I’ll be publishing some flight pictures of the plane very very soon :)

With love from Kansas,

Allan