Bridge Building: In Progress by Becca H. '12

The culmination of what I've learned in civil engineering

In order to graduate from Course 1, you have to take a class called 1.013 (Senior Civil and Environmental Engineering Design, for those not yet versed in MIT speak). There are a LOT of components to this class, but one of the most fun is building, well, a bridge. It is pretty much what it sounds like. We are given a general prompt and sent on our way:

Savannah climates have streams that are dry or have low flow most of the year and can be easily crossed by foot during these periods. However, during the flood stages, such streams represent impassable obstacles. A footbridge that can be quickly assembled from easily available materials will be designed, detailed, fabricated, built and tested by the student teams.

There are a few requirements, such as failure criteria, and that the bridge has to be 10 ft long, with a 2 ft wide deck and 2-3 ft clearance above the water level, but other than that, it is really up to our imaginations (and engineering skills). Oh, and it is supposed to hold 2000 lbs of distributed load (and hopefully the building team as well).

Failure Criteria

Collapse Criteria

Collapse Load > 1.5 Max Working Load

Serviceability

Maximum allowable LL deflection < L/360

Maximum allowable TL deflection < L/240

Loads

LL: 100 lbs./sq.ft.

After spending the past few semesters in classes like 1.050, 1.035 and 1.036 learning the fundamentals of structural design, this is a chance to build a structure and test it. Even though I will likely have very little to do with structural engineering in the future (I am heading into a little sub-field of civil engineering known as transportation), it has been a lot of fun to see our design come to fruition. When I was younger, I wanted to be a bridge engineer and spent much of my childhood building and testing bridges in my basement. Most of my bridges then were maybe a foot long, rather than ten, so I am enjoying doing a full-scale project.

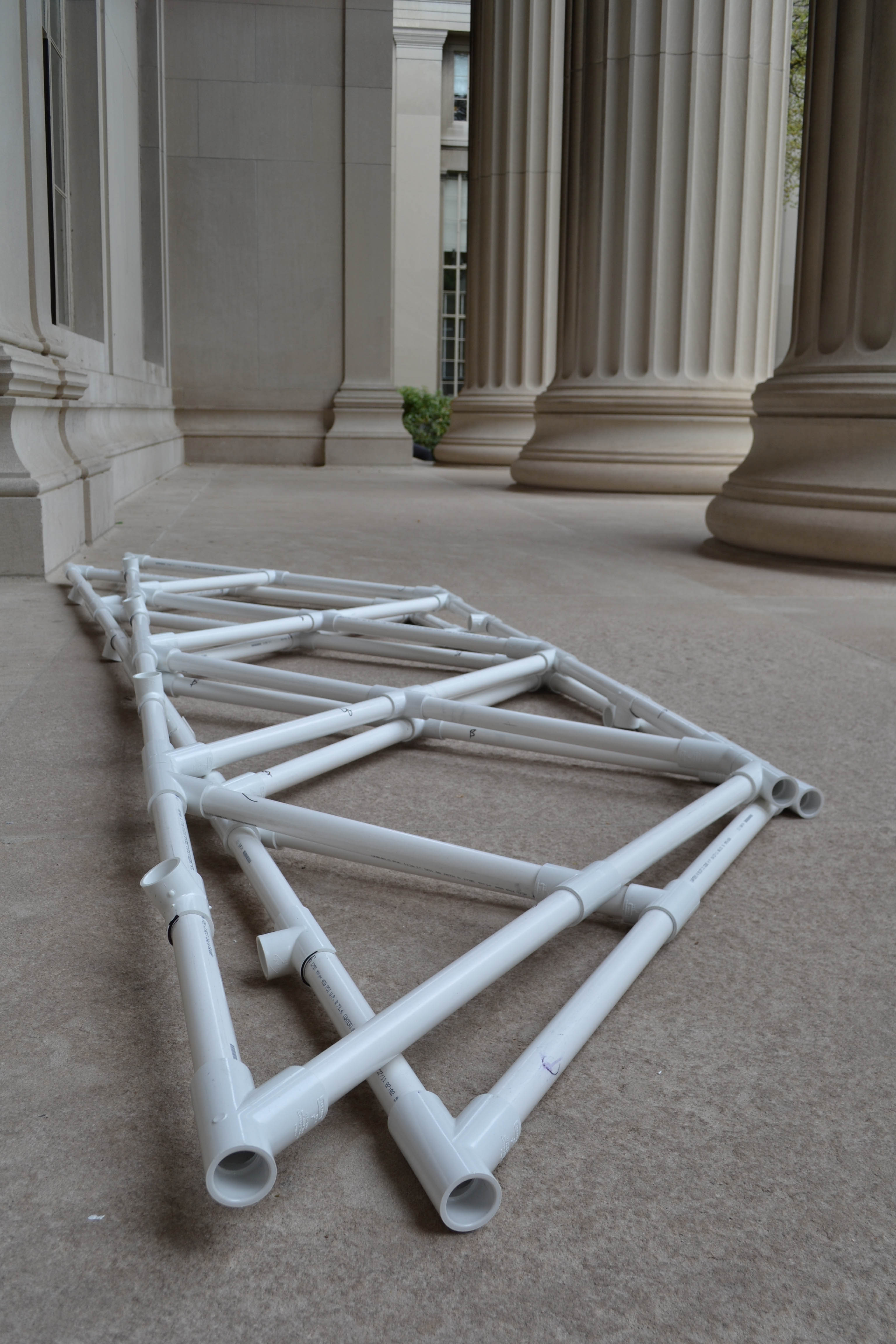

Our completed trusses

Best part?

Easily carried by one person

My team decided to go a bit of a different direction that most and try and come up with an innovative material to use for our bridge. We have a pretty simple design (a truss bridge), but are using PVC and PVC connectors to construct the bridge. Although PVC isn’t necessarily the most readily available material in developing countries ( a minor part of the project), it can be quickly assembled and is very light, making it ideal for emergency situations where aid might be brought in, and has the benefit of being easily moved and stored. We are still in the process of building our bridge, but have almost finished our frame, with only the deck left to complete.

A team effort to get the angles in

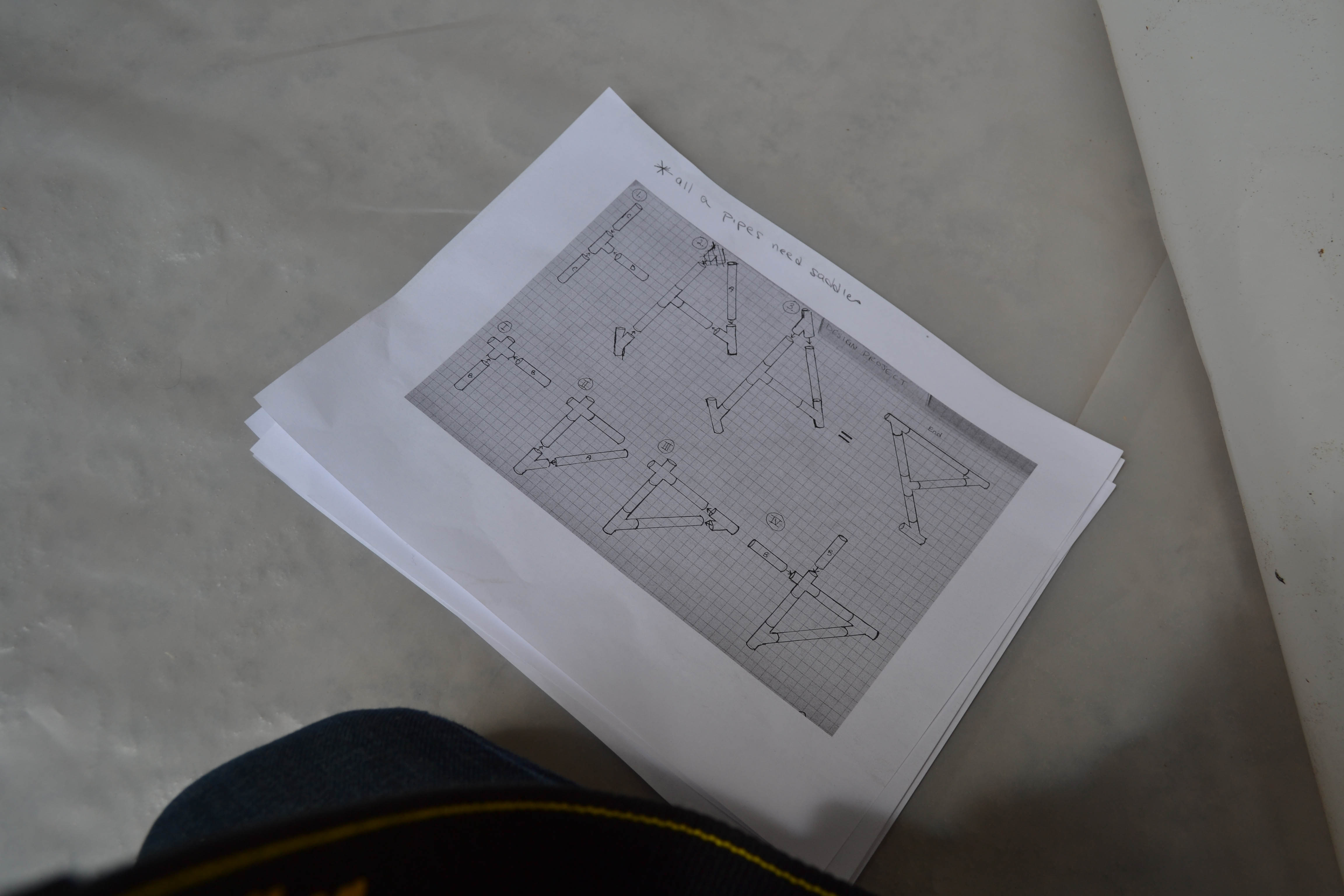

Our wonderful construction diagrams, courtesty of Megan O. ’12

Building space? The porch off Lobby 10.

Well-ventilated area? Check.

Some teams went a different direction…

If you are in the Cambridge/MIT area next Wednesday, May 9th, come out in front of the Student Center between about 12:30pm and 4pm to watch us test our bridges. This basically involves loading them with 2000 lbs of concrete blocks and hoping that our calculations were correct. So come watch!